Hydrogen Peroxide Treatment

Stored slurry can emit up to 30 % of farm methane emissions.

Hydrogen peroxide treatment stops gases forming and boosts nitrogen retention.

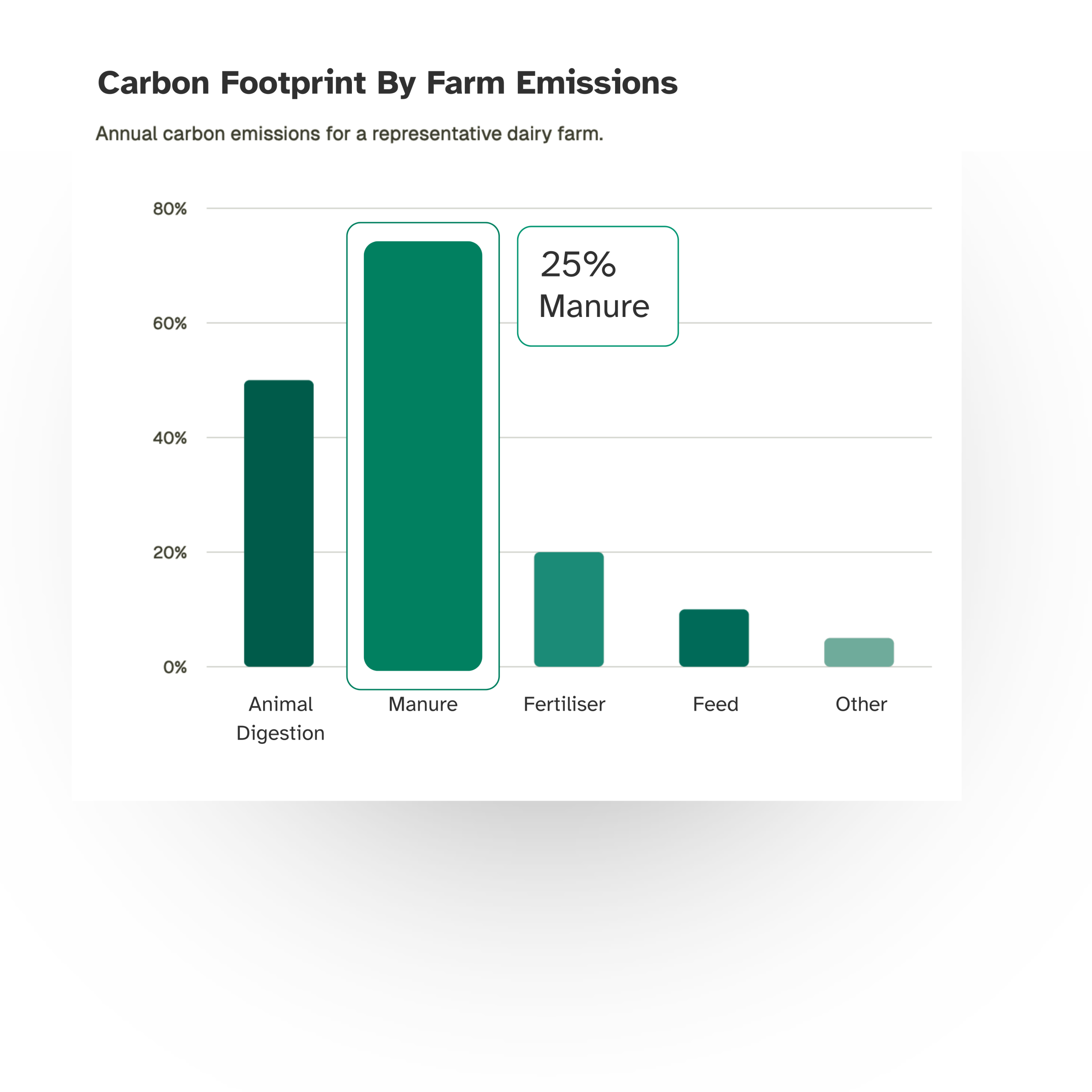

The Climate Issue

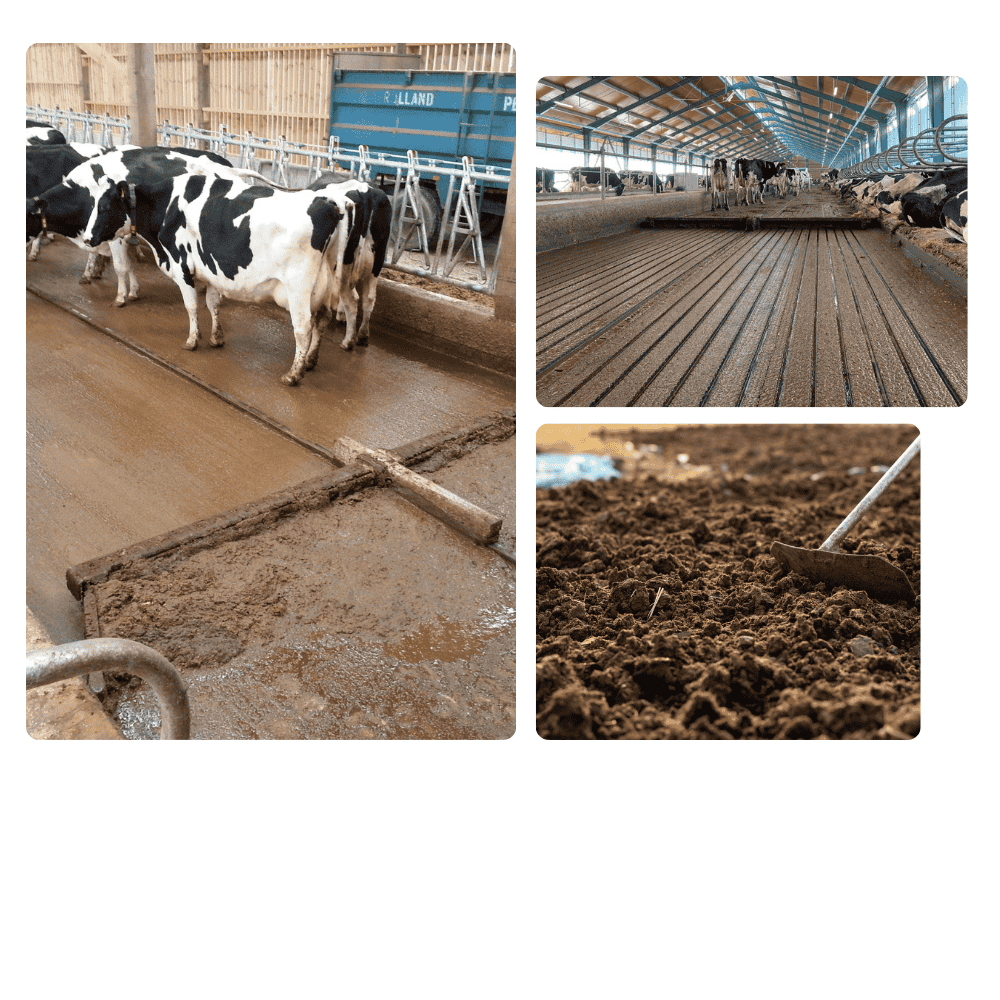

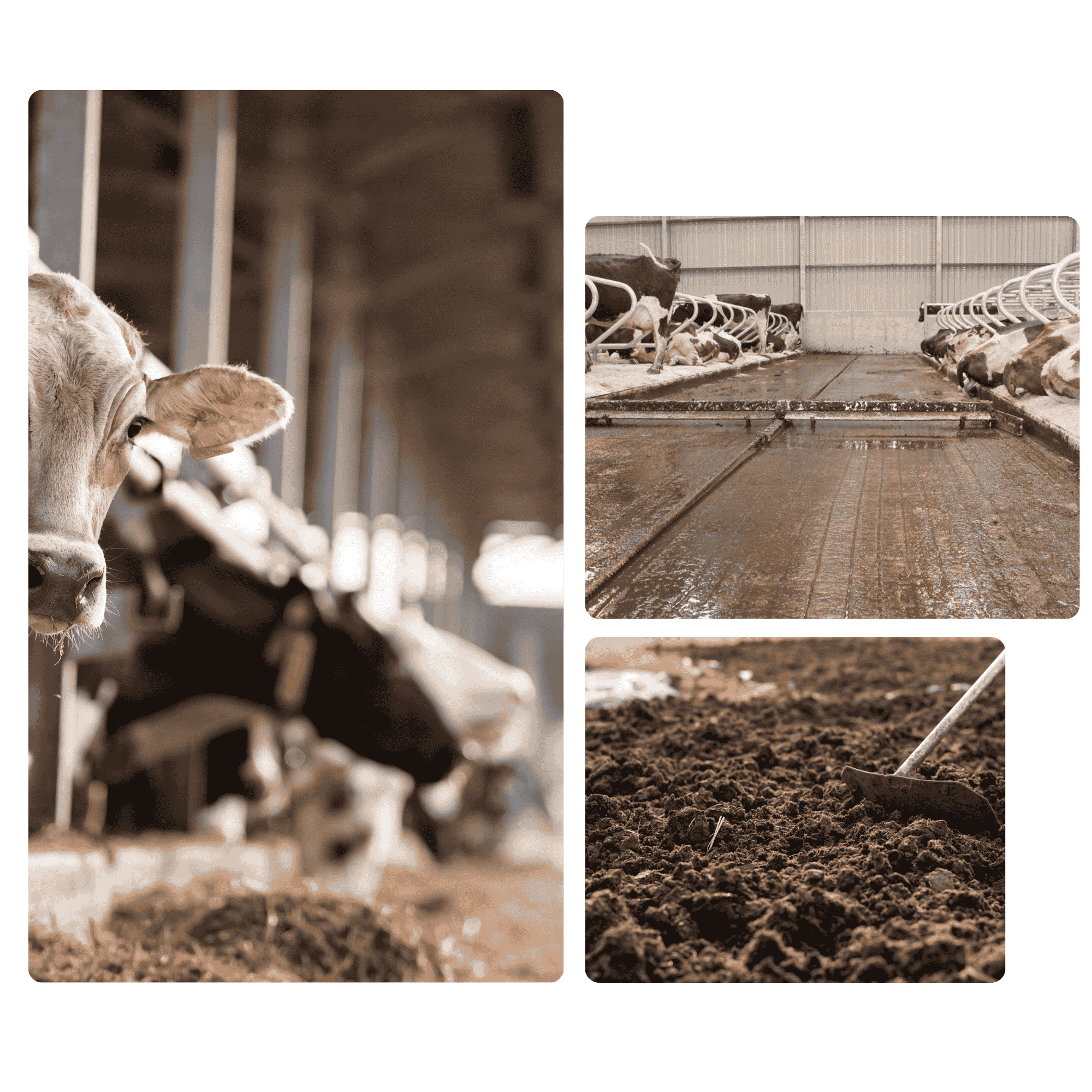

Slurry storage is one of the hidden emission hotspots on a dairy farm. Even before spreading, bacteria in slurry tanks convert carbon into methane and turn nitrogen into ammonia gas. These losses reduce fertiliser value and pollute the atmosphere.

Methane is over 25 times more potent than CO₂, and ammonia contributes to poor air quality and nitrous oxide formation in soils. Left untreated, slurry can leak both. Storing for weeks or months increases the risk. Every bubble that escapes is a missed opportunity.

The Solution: Slurry Storage

Hydrogen peroxide treatment is a novel approach to stabilising slurry. By adding small amounts of H₂O₂ to slurry during early storage, microbial activity is reduced, and emissions are suppressed.

This treatment oxidises the slurry environment, halting methane-forming bacteria and reducing ammonia volatilisation. It also encourages nitrogen to stay in ammonium form, making it more available to crops.

Initial trials show H₂O₂-treated slurry can reduce methane emissions by up to 80 % and nearly eliminate ammonia losses during storage. That means less air pollution and more nutrient value in every litre.

Key Benefits when Stabilising Slurry

Cut Emissions

Hydrogen peroxide limits both methane and ammonia release by disrupting the microbial pathways responsible for gas formation, especially during the early storage period.

Nutrient Value

More nitrogen remains in a plant-ready form. This improves slurry’s fertiliser performance and reduces the need for additional synthetic inputs later in the season.

More Value

Treated slurry smells less, handles more easily, and delivers stronger results in fields. That means a cleaner environment and more consistent grass growth over time.

Impact of Slurry Treatment

Hydrogen peroxide-based slurry treatment offers a targeted way to reduce emissions from dairy farms by acting directly at the source, during storage.

Applied correctly, it reduces methane and ammonia without requiring changes to tanks or spreading equipment, though the additive cost remains a barrier without financial support.

Trials on Irish dairy farms show H₂O₂ treatment can:

- Reduce methane by up to 80 % during storage

- Cut ammonia losses by nearly 100 %

- Retain 4–8 kg more nitrogen per 1,000 gal of slurry

- Lower whole-farm GHG intensity by 2–4 % at full adoption

The impact below is based on farm-scale modelling in Irish pasture-based systems.

|

Scenario

|

GHG Emissions

|

% GHG Reduction

|

|---|---|---|

|

0% Adoption |

0.960 kg CO₂-eq/kg milk |

0% kg CO₂-eq/kg milk |

|

50% Adoption |

0.936 kg CO₂-eq/kg milk |

2.5% kg CO₂-eq/kg milk |

|

100% Adoption |

0.922 kg CO₂-eq/kg milk |

4% kg CO₂-eq/kg milk |

Considerations

Emerging Technology

Hydrogen peroxide treatment is still new and not yet widespread. While early trials are promising, long-term data is still limited. Adoption will depend on wider testing and farmer experience.

Safety & Handling

Peroxide must be handled with care. Dosing equipment and storage containers must be designed for safe use. Staff must be trained in dilution and application during early storage stages.

Timing & Conditions

Treatment works best if applied within the first days of storage. Delayed application reduces impact. Tanks must be clean, and agitation should be minimised during the treatment window.

Implementation

Adding H₂O₂ to your slurry management system is relatively easy, but timing and safety are essential. These simple steps can help you get started with confidence.

1. Set up dosing system. Work with a supplier to install small-scale peroxide dosing at the point of slurry entry or mixing zone.

2. Train for safety. Ensure all operators wear protective equipment and understand peroxide concentration, dilution, and safe application timing.

3. Treat early. Add hydrogen peroxide shortly after the slurry enters the tank. Ideally, within 24–48 hours to suppress microbes before they build up.

Behind the Research

ODOS Tech was founded by Cian White and Alejandro Vergara, two sustainability specialists with deep expertise in agricultural climate action.

Alejandro (left), a PhD in environmental engineering from University College Dublin, helps farmers measure their carbon footprint and implement mitigation strategies to reduce their impact. Cian (right), a researcher at Trinity College Dublin with a PhD in ecology, works on restoring nature to increase biodiversity on farms using satellite imagery to monitor habitats.

Together, they helped lead the carbon and nature-based work for the Farm Zero C project at Shinagh Farm, one of Europe’s first net-zero dairy pilots. In 2020, they launched ODOS, a platform that built smart, science-based tools to help agri-food businesses protect the environment and restore nature.

Research

Shinagh Farm Case Study

Field trials at Shinagh Dairy Farm showed that peroxide treatment during the first 56 days of storage cut methane by 80 % and eliminated nearly all ammonia loss. Treated slurry retained more nitrogen and led to improved pasture growth.

Teagasc Slurry Research

Early research highlights hydrogen peroxide as a potential low-cost treatment that complements other mitigation tools like LESS. It shows strong promise in Irish pasture systems with long slurry storage periods.

Innovation Outlook

While still in development, H₂O₂ treatment aligns with circular nutrient strategies. It could help farms meet tighter emission rules, enhance nitrogen efficiency, and reduce reliance on synthetic fertilisers over time.

Discover other Strategies

Slurry Acidification

Slurry acidification reduces fertiliser demand and cuts emissions by up to 5% during storage and spreading.

Slurry Treatment

Treating slurry with hydrogen peroxide cuts emissions by up to 4% and reduce methane by up to 80% during storage.

Slurry Cover

Covering slurry stores cuts emissions by up to 5% and saves €3,600 over 50 hectares per year by reducing synthetic fertiliser use.

Extending Grazing Season

Extending the grazing season cuts emissions by up to 2.7% and boosts milk revenue by nearly €3,000 per farm.

Antimethanogenic Feed Additives

Antimethanogenic feed additives cut methane emissions by up to 28% and cost €6975 per 93 cows annually.

Grass Biorefinery

Grass biorefineries replace soy protein, save €3,000 in feed costs, and cut emissions by 8.9%.

Anaerobic Digestion

Sending slurry to anaerobic digestion can cut emissions by up to 9.4% and generate up to 400 MWh of energy per year.

Multispecies Swards

Switching to multispecies swards cuts emissions by up to 8.8% and saves €4,400 in fertiliser across 50 hectares.

Red Clover Silage

Using red clover silage cuts emissions by up to 8.2% and saves €2,000 in fertiliser across 20 hectares.

White Clover Silage

Incorporating white clover silage cuts emissions by up to 7.8% and saves €4,500 in fertiliser costs over 50 hectares.

Low Emission Slurry Spreading

Low-emission slurry spreading cuts ammonia by 60% and saves €45/h in fertiliser costs.

Genetic Selection

Genetic selection for high-EBI cows cuts emissions by up to 6.3% and boosts gains by €7,800 per 100 cows.

Protected Urea

Switching to protected urea cuts fertiliser costs and lowers emissions by up to 5.6% per kg of milk.

Ready to reduce emissions through Slurry Treatment?

Talk to our Carbon Footprint & Biodiversity experts on how we can help.